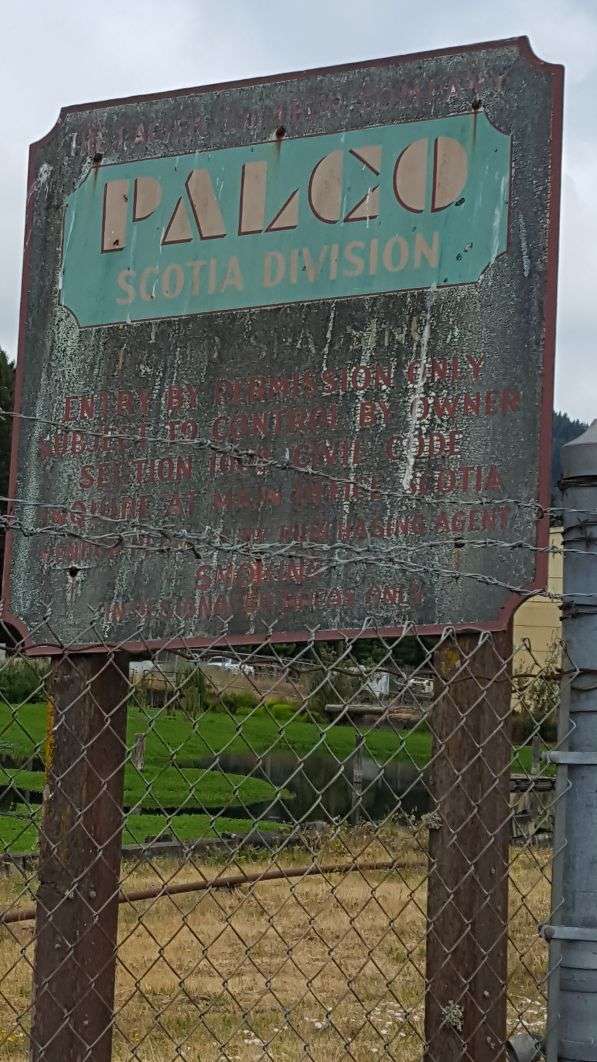

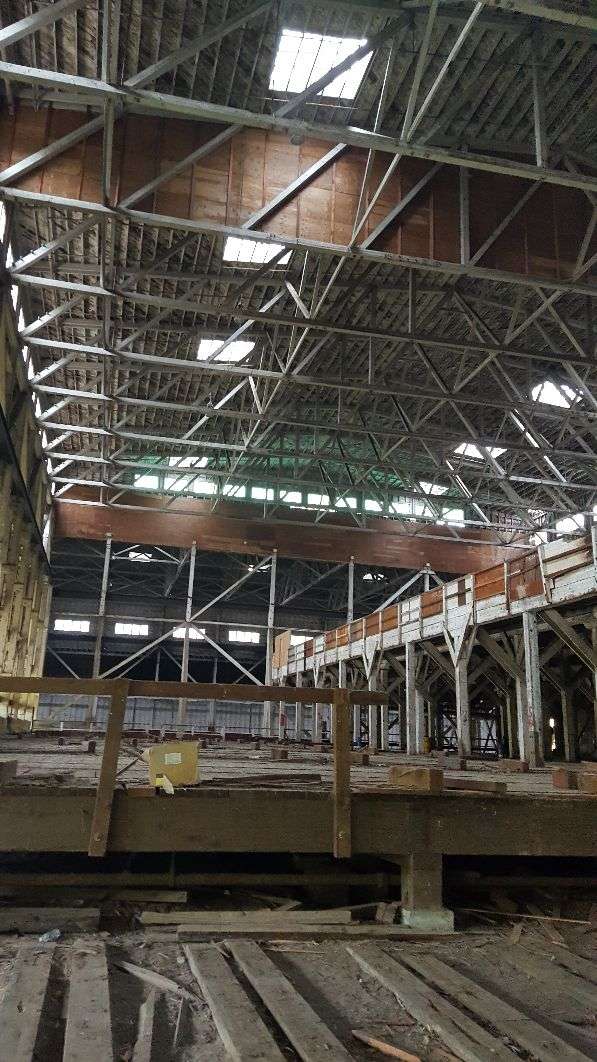

I think this huge building near the end of the line of buildings composing the Mill A complex was a kiln drying facility. This is the one with the winch along the side.

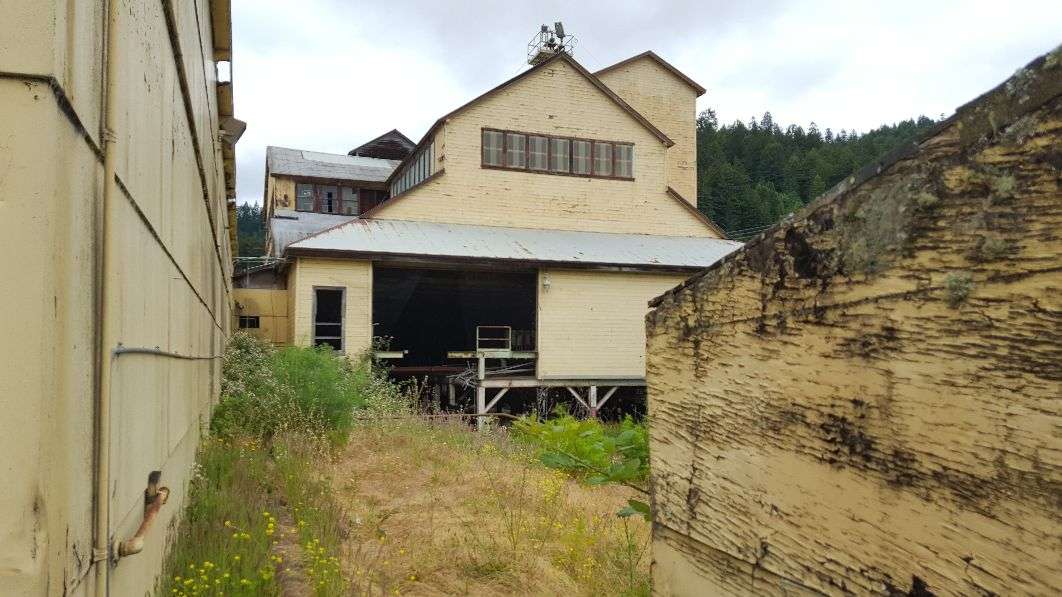

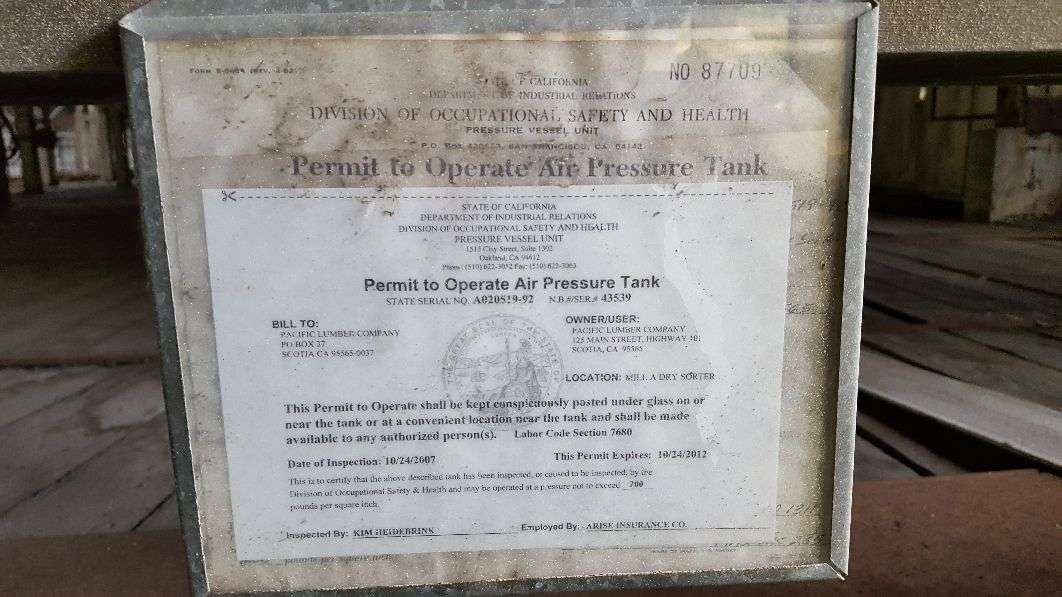

Judging by this air compressor pressure tank permit, this building was still in use until sometime between 2007 and 2012. Think I took these pics in 2015. I see now that is sez "Mill A Dry Sorter"....

Last edited: